SEARCULAR Ports

Published 16/07/2025

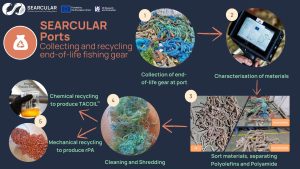

The port based solutions team are developing a ‘Blue Point’ for ports in the Basque Country to effectively collect and manage end-of-life (EOL) fishing gear. Currently most gear that is collected is either incinerated or put into landfill – we want to change that. Our model will support effective collection and management of EOL fishing gear at ports to allow for effective recycling of the ‘waste’ material. Looking across the whole supply chain from ports to recycling, we aim to valorise waste material through collecting, sorting, conditioning, and recycling into new plastic products ensuring a “plastic2plastic” strategy.

Looking back over the first 18 months of SEARCULAR, what are you most proud of?

Paule: When we set out our objectives for SEARCULAR, we were hoping to secure 5 tonnes of material for processing over the whole project lifetime, but one of our biggest successes in the first year was to obtain this amount very quickly, and then double this amount to a current total of 10 tonnes. This is thanks to being able to establish close working relationships with different institutions and ports. We are particularly pleased to be working closely with the Basque Government, who have been supportive of SEARCULAR, to collect a lot of this material.

These fishing gears came from a variety of sources, including collection of discarded gear at ports and of gear discarded at sea. As such we have had a mix of different materials and gear types and we have been able to sort and classify 88% of the material. The lost weight is mostly due to water, sand and biofouling on the gears which are removed in the cleaning process. This process has highlighted the need for adequate collection and storage facilities to facilitate easier sorting of materials and to prevent materials from getting wet during storage and processing. This is a complex process and there is a clear need to improve the design of fishing gear to support future recycling. As part of SEARCULAR, we are investigating both mechanical and chemical recycling of these materials.

As a team, we have gained so much knowledge from working directly with stakeholders such as ports, institutions and the government which has been invaluable and will shape our research going forward.

An example of process from collection of end-of-life fishing gear at ports to the production of secondary raw material.

What’s next for SEARCULAR’s Port-based solutions?

Paule: The next chapter for our work is very exciting. We have already processed and begun our initial pyrolysis lab tests with Plastic Energy and we are eagerly awaiting the results of these tests. Pyrolysis is a method of chemical recycling that produces an oil that can be used to make new plastic products. This is a way of utilising materials from fishing gear that is not suitable for more traditional mechanical recycling.

We are also developing a reverse logistics model with VTT. Reverse logistics is the process of defining how a product at the ‘end’ of its life with a consumer is returned to industry. In this case, we will be defining how end-of-life fishing gear is collected, processed, recycled and then reused by manufacturers to make new products.

These activities are helping us ‘close the circle’ for fishing gear. Together with our partners and stakeholders we are working to reduce waste and marine litter from fishing. Understanding the process and requirements for the efficient recycling of waste fishing gear from the moment the material is collected at the port, through transportation, where and how to store it, the classification and separation of different materials, crushing and washing recyclable materials, moving the selected materials to pyrolysis where we will produce and an oil that can be made into new plastic materials, with all the benefit of it being recycled plastic. We are excited to take on this challenge with our partners and develop solutions that work for all involved.